The gasketed plate heat exchanger is one of the most significant innovations in heat transfer technology, providing an efficient and compact method for exchanging heat between fluids in various industrial applications. The journey of this invention spans over a century, with many advancements in design, materials, and functionality.

Early Beginnings and Inventions (1870s-1900s)

The concept of heat exchange dates back to the 19th century. In 1878, Swedish engineer Gustaf de Laval made a significant breakthrough by inventing the centrifugal milk separator. This device laid the foundation for future developments in heat exchangers, as it required precise control of fluid flow. While his invention focused on the dairy industry, it underscored the importance of efficient heat transfer mechanisms in industrial processes.

Another milestone occurred in 1882 when Carl von Linde, a German engineer known for his work in refrigeration technology, developed the first closed-cycle refrigeration system. His work on thermodynamics and heat transfer further accelerated the exploration of more efficient heat exchange systems.

The Birth of Gasketed Plate Heat Exchangers (1920s)

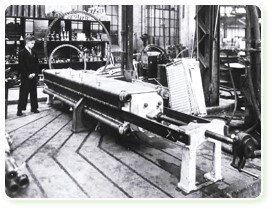

The first recognizable gasketed plate heat exchanger was invented in 1923 by Dr. Richard Seligman in the United Kingdom. Seligman, an engineer and inventor, created a device that consisted of a series of thin, corrugated metal plates stacked together, with gaskets between the plates to prevent leakage. This innovation allowed for a greater surface area for heat transfer, making it much more efficient than previous shell-and-tube heat exchangers. The design also allowed for easy disassembly, cleaning, and maintenance.

Seligman’s invention was originally used in the food and dairy industries, where hygiene and temperature control were critical. By the 1930s, it was being adopted by industries that required compact and efficient heat exchangers for various applications, such as power generation, petrochemicals, and chemical processing.

The Development of Gasketed Plate Heat Exchangers (1950s-1970s)

After World War II, the demand for more efficient industrial processes surged, leading to further improvements in gasketed plate heat exchanger technology. In the 1950s, companies like Alfa Laval (founded by Gustaf de Laval) and GEA Group began to refine and manufacture GPHEs on a larger scale. These new models were designed to withstand higher pressures and temperatures, making them suitable for a wider range of industries, including HVAC, energy production, and oil refining.

Advancements in gasket materials also played a crucial role. New synthetic rubbers and polymers allowed for gaskets that could endure harsh chemicals and extreme temperatures, significantly expanding the application of gasketed plate heat exchangers.

Modern Gasketed Plate Heat Exchangers (1980s-Present)

The 1980s marked a new era for gasketed plate heat exchangers, as manufacturing techniques and computational methods improved. Engineers could now optimize plate designs using computer simulations, allowing for even more efficient heat transfer and energy conservation. Companies like SWEP and Tranter began specializing in compact heat exchangers, offering customized solutions for specific industrial needs.

One of the most important developments during this time was the use of stainless steel and titanium in plate construction, which allowed GPHEs to operate in highly corrosive environments and at much higher temperatures and pressures. The flexibility of these materials also meant that gasketed plate heat exchangers could be produced in a variety of sizes, from small units for residential heating systems to large industrial systems capable of handling massive energy loads.

In 1997, Alfa Laval introduced the ClipLine, a new range of gasketed plate heat exchangers designed for easier installation and reduced maintenance. This innovation was particularly well-suited for industries that required frequent cleaning and inspection, such as food processing and pharmaceuticals.

Today, gasketed plate heat exchangers are used in a wide range of industries, including chemical processing, oil and gas, marine applications, renewable energy systems, and more. The combination of energy efficiency, cost-effectiveness, and ease of maintenance has made them a preferred choice for engineers and industrial designers worldwide.

Key Scientists and Engineers in Gasketed Plate Heat Exchanger Development

Gustaf de Laval: A Swedish engineer who invented the centrifugal separator in 1878 and laid the groundwork for modern heat exchangers.

Carl von Linde: Known for his pioneering work in refrigeration and thermodynamics, Linde contributed to the development of early heat transfer systems.

Dr. Richard Seligman: The British inventor of the first commercial gasketed plate heat exchanger in 1923, whose design is the basis for the modern GPHE.