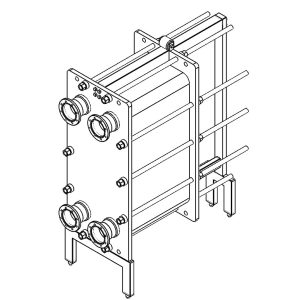

A gasket plate heat exchanger is a type of heat exchanger that consists of multiple thin plates with gaskets between them. These plates are typically made of stainless steel or other metals and are corrugated to increase their surface area for heat transfer.

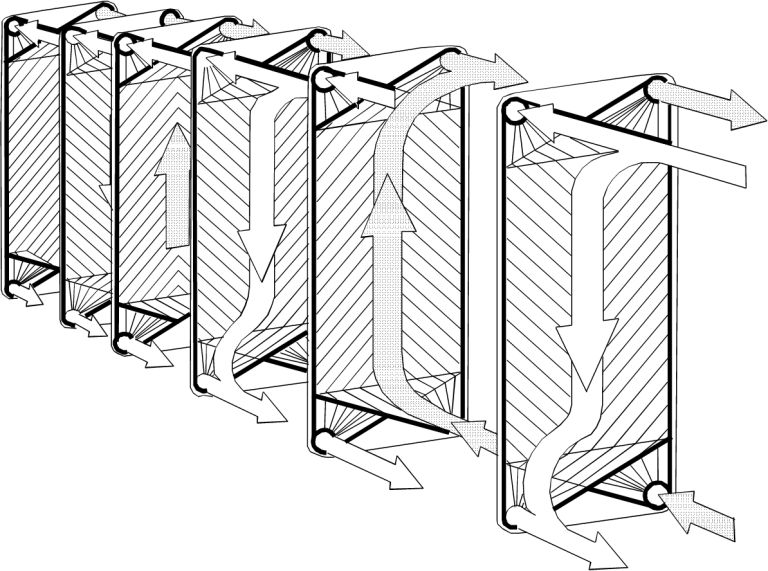

Fluids flow on either side of the plates, allowing heat to transfer from one fluid to the other through the plate material. The gaskets create a seal between the plates, preventing the fluids from mixing and ensuring efficient heat transfer.

These heat exchangers are commonly used in HVAC systems, refrigeration, chemical processing, and other industrial applications due to their high efficiency, compact size, and ease of maintenance. They can handle high pressures and temperatures and are versatile in handling different types of fluids.

Maintenance typically involves periodically inspecting and replacing gaskets as needed to maintain the integrity of the seal. Proper installation and maintenance are crucial for optimal performance and longevity of gasket plate heat exchangers.

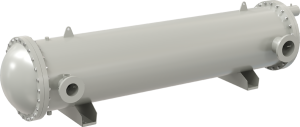

Gasket Plate Heat Exchangers vs. Shell and Tube Heat Exchangers

Gasket Plate Heat Exchangers (GPHE) represent a modern alternative to traditional shell and tube designs, offering several distinct advantages:

1. Compact Size: PLATE HEAT EXCHANGER are significantly smaller and lighter than SHELL AND TUBE HEAT EXCHANGER, occupying less space and reducing installation costs.

2. High Heat Transfer Efficiency: The design of Plate Heat Exchanger (PHE), with thin, corrugated plates, promotes turbulent flow and enhances heat transfer rates, often outperforming Shell & Tube Heat Exchanger (STHE) in thermal efficiency.

3. Lower Fluid Hold-up: PHEs have lower volume capacities compared to STHEs, reducing the amount of fluid required to fill the exchanger and decreasing operational costs.

4. Ease of Maintenance: PHEs are easier to disassemble and clean due to their modular plate design, which allows for quick access to individual plates for inspection or replacement.

5. Versatility: Suitable for a wide range of applications, including HVAC systems, food processing, pharmaceuticals, and industrial processes where space constraints or efficiency are critical factors.

Our flagship product, the gasket plate heat exchanger, exemplifies superior design and engineering. Renowned for its high efficiency and durability, it provides exceptional thermal performance across diverse industrial applications. Engineered to meet the highest standards, it ensures reliable and optimal heat transfer in demanding environments.